Ammonium alginate (E403)

- E403

- Heat resistant, fat soluble, water binding properties

- Gelling agent

- Coating agent

On Demand weeks

Introduction: Ammonium alginate (E403)

What is Ammonium alginate?

Ammonium alginate is a chemical compound derived from brown seaweed. It is a white or yellowish powder that is commonly used as a thickening or gelling agent in the food industry. It is also used in the pharmaceutical industry as a tablet coating, and in the textile industry as a sizing agent. In addition, ammonium alginate has been used in the medical field as a wound dressing and as a scaffold for tissue engineering.

What are the uses for Ammonium alginate?

Ammonium alginate is used in the food industry as a thickening agent and gelling agent in a variety of foods, including ice cream, puddings, and jellies. Additionally Ammonium alginate is being used in the pharmaceutical industry as a tablet coating to improve the stability and appearance of tablets.

The textile industry uses Ammonium alginate as a sizing agent in the textile industry to improve the strength and durability of fabrics. Ammonium alginate has been used in the medical field as a wound dressing to promote healing, and as a scaffold for tissue engineering to encourage the growth of new cells.

Ammonium alginate is also used in the cosmetics industry as an emulsion stabilizer and in the paper industry as a retention aid.

Can Ammonium alginate be used in food?

Yes, ammonium alginate is commonly used as a thickening and gelling agent in the food industry. It is often used to stabilize emulsions, to improve the texture and mouthfeel of foods, and to prevent syneresis (weeping) in products such as jellies and gelled desserts. Ammonium alginate is generally regarded as safe for use in food, and it has been approved for use as a food additive in many countries around the world.

How long does it take Ammonium alginate to set?

The time it takes for ammonium alginate to set will depend on a variety of factors, including the concentration of the alginate solution, the pH of the solution, the temperature of the solution, and the presence of other ingredients.

In general, ammonium alginate will begin to gel within a few minutes of being mixed with water or another liquid, but it may take several hours or longer for the gel to fully set. The gelling process can be accelerated by increasing the concentration of the alginate solution or by adding a small amount of a gelling agent, such as calcium chloride.

Does Ammonium alginate stick to itself?

Yes, ammonium alginate can stick to itself when it is in a gel form. When mixed with water or another liquid, ammonium alginate forms a viscous, gel-like substance that can be molded or shaped. When two pieces of the gel are pressed together, they will tend to stick to each other.

This property can be useful in applications where the gel is used as a bonding or sealing agent, such as in the construction industry or in the production of pharmaceutical tablets. However, it can also be a disadvantage in some situations, as the gel may be difficult to separate or remove once it has adhered to a surface.

What is the difference between Alginate and Ammonium Alginate?

Alginate and ammonium alginate are both chemical compounds derived from brown seaweed. They are both commonly used as thickening and gelling agents, and they have many similar properties and applications.

The main difference between the two compounds is that alginate is a salt of alginic acid, while ammonium alginate is a salt of alginic acid that has been neutralized with ammonium hydroxide. This means that alginate is slightly acidic, while ammonium alginate is slightly basic. The pH of a solution can affect the gelling properties of alginate and ammonium alginate, so the type of alginate used may be chosen based on the pH of the application.

In addition, alginate and ammonium alginate may have slightly different physical and chemical properties, such as viscosity and solubility, which may affect their suitability for certain applications.

Typical applications: Ammonium alginate (E403)

Typical applications

More commonly known under the E number "E403", ammonium alginate is a compound between ammonium acid and alginic acid.

Alginic acid is a naturally present, edible polysaccharide obtained from brown algae. Together with the chemical additive ammonium acid, they produce ammonium alginate. The final product has great heat resistant, fat soluble properties and the ability to bind water.

In the food industry, ammonium alginate is mostly used as a gelling, thickening and coating medium. In combination with calcium ions, E403 forms gels that are stable to cooking and freezing. For this reason, its use as a coating agent to protect food from drying out and to ensure stability during freezing and defrosting is very popular.

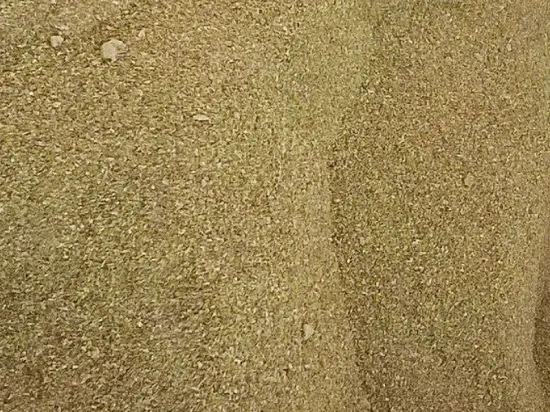

This product is available in the following forms: Ammonium Alginate powder.

ALGANEX certificate system

Reply within twelve hours